JLL-AHN42F型安全回流阀

产品概述 Product Description

AHN42F型安全回流阀适用于液化石油气泵出口的液相出口管路上,用于超压介质的安全回流,标准回流压差大于0.5MPa时液化石油气能自动回流入罐。可调整回流压差为0.3~0.8MPa,或按用户要求确定,当泵前压力超过规定值时,阀门自动开启,并起安全回流作用,保证设备和管路的安全运行。

【安全回流阀主要设计参数】 Main design parameters of safety reflux valve

|

设计、制造 |

法兰连接 |

结构长度 |

公称通径 |

公称压力 |

|

GB/T12243 |

JB/T79-94、GB9113-2000 |

GB12221-89 |

DN25~DN300mm |

PN1.6、2.5、4.0MPa |

【安全回流阀主要性能参数】 Main performance parameters of safety reflux valve

|

公称压力 |

壳体试验 |

密封试验 |

开启压力 |

适用介质 |

适宜温度 |

|

1.6 |

2.4 |

0.9PK |

用户确定 |

液化气、天然气 等非腐蚀性介质 |

-40~+80℃ |

|

2.5 |

3.75 |

||||

|

4.0 |

4.4 |

【安全回流阀主要零部件材料】 Main component materials of safety reflux valve

|

NO. |

零件名称 |

AHN42F-C A42F-C 材料 |

|

1 |

阀座 |

2Cr13 |

|

2 |

阀体 |

WCB |

|

3 |

调节圈 |

2Cr13 |

|

4 |

反冲盘 |

2Cr13 |

|

5 |

阀瓣 |

2Cr13+PTFE |

|

6 |

导向套 |

2Cr13 |

|

7 |

阀盖 |

ZG230-450 |

|

8 |

弹簧 |

50CrVA |

|

9 |

阀杆 |

2Cr13 |

|

10 |

调整螺杆 |

45 |

|

11 |

阀帽 |

ZG200-400 |

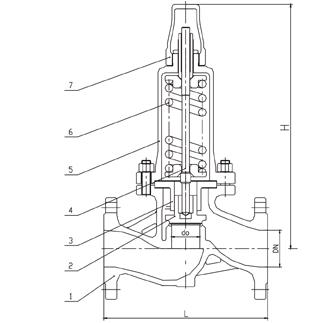

结构示意图 Structure Diagram

【安全回流阀主要外形尺寸】 Main external dimensions of safety reflux valve

|

型号 |

公称通径 |

do |

D |

K |

g |

g1 |

b |

f |

f1 |

Z-ød |

DN’ |

D1 |

K1 |

g2 |

b1 |

f’ |

Z1-ød1 |

L |

L1 |

≈H |

|

AH42F-16C

|

20 |

15 |

105 |

75 |

/ |

55 |

16 |

2 |

/ |

4-14 |

25 |

115 |

85 |

65 |

16 |

2 |

4-14 |

110 |

95 |

378 |

|

25 |

16 |

115 |

85 |

/ |

65 |

16 |

2 |

/ |

4-14 |

32 |

140 |

100 |

78 |

18 |

2 |

4-18 |

110 |

95 |

378 |

|

|

32 |

20 |

140 |

100 |

/ |

78 |

18 |

2 |

/ |

4-18 |

40 |

150 |

110 |

85 |

18 |

3 |

4-18 |

115 |

100 |

378 |

|

|

40 |

25 |

150 |

110 |

/ |

85 |

18 |

3 |

/ |

4-18 |

50 |

165 |

125 |

100 |

20 |

3 |

4-18 |

120 |

110 |

406 |

|

|

50 |

32 |

165 |

125 |

/ |

100 |

20 |

3 |

/ |

4-18 |

65 |

185 |

145 |

120 |

20 |

3 |

4-18 |

135 |

120 |

450 |

|

|

65 |

40 |

185 |

145 |

/ |

120 |

20 |

3 |

/ |

4-18 |

80 |

200 |

160 |

135 |

20 |

3 |

8-18 |

160 |

140 |

520 |

|

|

80 |

50 |

200 |

160 |

/ |

135 |

20 |

3 |

/ |

8-18 |

100 |

220 |

180 |

155 |

22 |

3 |

8-18 |

170 |

135 |

525 |

|

|

100 |

65 |

220 |

180 |

/ |

155 |

22 |

3 |

/ |

8-18 |

125 |

250 |

210 |

185 |

22 |

3 |

8-18 |

195 |

175 |

690 |

|

|

125 |

80 |

250 |

210 |

/ |

185 |

22 |

3 |

/ |

8-18 |

150 |

285 |

240 |

210 |

24 |

3 |

8-23 |

210 |

190 |

780 |

|

|

150 |

100 |

285 |

240 |

/ |

210 |

24 |

3 |

/ |

8-23 |

175 |

310 |

270 |

240 |

26 |

3 |

8-23 |

255 |

230 |

838 |

|

|

200 |

125 |

340 |

295 |

/ |

265 |

26 |

3 |

/ |

12-23 |

250 |

405 |

355 |

320 |

30 |

3 |

12-26 |

300 |

260 |

992 |

|

|

250 |

150 |

405 |

355 |

/ |

320 |

30 |

3 |

/ |

12-26 |

300 |

460 |

410 |

375 |

30 |

4 |

12-26 |

350 |

320 |

1266 |

|

|

300 |

220 |

460 |

410 |

/ |

375 |

30 |

4 |

/ |

12-26 |

400 |

580 |

525 |

485 |

36 |

4 |

16-30 |

370 |

350 |

1283 |

|

|

350 |

250 |

520 |

470 |

/ |

435 |

34 |

4 |

/ |

16-26 |

500 |

715 |

650 |

608 |

44 |

4 |

20-34 |

500 |

450 |

1520 |

|

|

400 |

280 |

580 |

525 |

/ |

485 |

36 |

4 |

/ |

16-30 |

500 |

715 |

650 |

608 |

44 |

4 |

20-34 |

500 |

450 |

1530 |

|

|

AH42F-25 |

20 |

15 |

105 |

75 |

/ |

55 |

16 |

2 |

/ |

4-14 |

25 |

115 |

85 |

65 |

16 |

2 |

4-14 |

110 |

95 |

378 |

|

25 |

16 |

115 |

85 |

/ |

65 |

16 |

2 |

/ |

4-14 |

32 |

140 |

100 |

78 |

18 |

2 |

4-18 |

110 |

95 |

378 |

|

|

32 |

20 |

140 |

100 |

/ |

78 |

18 |

2 |

/ |

4-18 |

40 |

150 |

110 |

85 |

18 |

3 |

4-18 |

115 |

100 |

378 |

|

|

40 |

25 |

150 |

110 |

/ |

85 |

18 |

3 |

/ |

4-18 |

50 |

165 |

125 |

100 |

20 |

3 |

4-18 |

120 |

110 |

406 |

|

|

50 |

32 |

165 |

125 |

/ |

100 |

20 |

3 |

/ |

4-18 |

65 |

185 |

145 |

120 |

20 |

3 |

4-18 |

135 |

120 |

450 |

|

|

65 |

40 |

185 |

145 |

/ |

120 |

22 |

3 |

/ |

8-18 |

80 |

200 |

160 |

135 |

20 |

3 |

8-18 |

160 |

140 |

520 |

|

|

80 |

50 |

200 |

160 |

/ |

135 |

22 |

3 |

/ |

8-18 |

100 |

220 |

180 |

155 |

22 |

3 |

8-18 |

170 |

135 |

525 |

|

|

100 |

65 |

230 |

190 |

/ |

160 |

24 |

3 |

/ |

8-23 |

125 |

250 |

210 |

185 |

22 |

3 |

8-18 |

195 |

175 |

690 |

|

|

125 |

80 |

270 |

220 |

/ |

188 |

28 |

3 |

/ |

8-26 |

150 |

285 |

240 |

210 |

24 |

3 |

8-23 |

210 |

190 |

780 |

|

|

150 |

100 |

300 |

250 |

/ |

218 |

30 |

3 |

/ |

8-26 |

175 |

310 |

270 |

240 |

26 |

3 |

8-23 |

255 |

230 |

838 |

|

|

200 |

125 |

360 |

310 |

/ |

278 |

34 |

3 |

/ |

12-26 |

250 |

405 |

355 |

320 |

30 |

3 |

12-26 |

300 |

260 |

992 |

|

|

250 |

150 |

425 |

370 |

/ |

332 |

36 |

3 |

/ |

12-30 |

300 |

460 |

410 |

375 |

30 |

4 |

12-26 |

350 |

320 |

1266 |

|

|

300 |

220 |

485 |

430 |

/ |

390 |

40 |

4 |

/ |

16-30 |

400 |

580 |

525 |

485 |

36 |

4 |

16-30 |

370 |

350 |

1283 |

|

| AH42F-40 A42F-40 |

20 | 15 | 105 | 25 | 51 | 55 | 16 | 2 | 4 | 4-14 | 25 | 115 | 85 | 65 | 16 | 2 | 4-14 | 110 | 95 | 378 |

| 25 | 16 | 115 | 85 | 58 | 65 | 16 | 2 | 4 | 4-14 | 32 | 140 | 100 | 78 | 18 | 2 | 4-18 | 110 | 95 | 378 | |

| 32 | 20 | 140 | 100 | 66 | 78 | 18 | 2 | 4 | 4-18 | 40 | 150 | 110 | 85 | 18 | 3 | 4-18 | 115 | 100 | 378 | |

| 40 | 25 | 150 | 110 | 76 | 85 | 18 | 3 | 4 | 4-18 | 50 | 165 | 125 | 100 | 20 | 3 | 4-18 | 120 | 110 | 406 | |

| 50 | 32 | 165 | 125 | 88 | 100 | 20 | 3 | 4 | 4-18 | 65 | 185 | 145 | 120 | 20 | 3 | 4-18 | 135 | 120 | 450 | |

| 65 | 40 | 185 | 145 | 110 | 120 | 22 | 3 | 4 | 8-18 | 80 | 200 | 160 | 135 | 20 | 3 | 8-18 | 160 | 140 | 520 | |

| 80 | 50 | 200 | 160 | 121 | 135 | 22 | 3 | 4 | 8-18 | 100 | 220 | 180 | 155 | 22 | 3 | 8-18 | 170 | 135 | 525 | |

| 100 | 65 | 235 | 190 | 150 | 160 | 24 | 3 | 4.5 | 8-23 | 125 | 250 | 210 | 185 | 22 | 3 | 8-18 | 195 | 175 | 690 | |

| 125 | 80 | 270 | 220 | 176 | 188 | 28 | 3 | 4.5 | 8-26 | 150 | 285 | 240 | 210 | 24 | 3 | 8-23 | 210 | 190 | 780 | |

| 150 | 100 | 300 | 250 | 204 | 218 | 30 | 3 | 4.5 | 8-26 | 175 | 310 | 270 | 240 | 26 | 3 | 8-23 | 255 | 230 | 838 | |

| 200 | 125 | 375 | 320 | 260 | 282 | 38 | 3 | 4.5 | 12-30 | 250 | 405 | 355 | 320 | 30 | 3 | 12-26 | 300 | 260 | 992 | |

| 250 | 150 | 450 | 385 | 313 | 345 | 42 | 3 | 4.5 | 12-34 | 300 | 460 | 410 | 375 | 30 | 4 | 12-26 | 350 | 320 | 1266 |

【安全回流阀安装说明】 Installation instructions for safety reflux valve

①安全回流阀都应水平安装。

②安全回流阀出口处应无阻力,避免产生受压现象。

③安全回流阀在安装前应专门测试,并检查其官密封性。

④对使用中的安全回流阀应作定期检查。

加利利温馨提醒:以上所有资料仅供参考,具体参数请电话:021-56350477